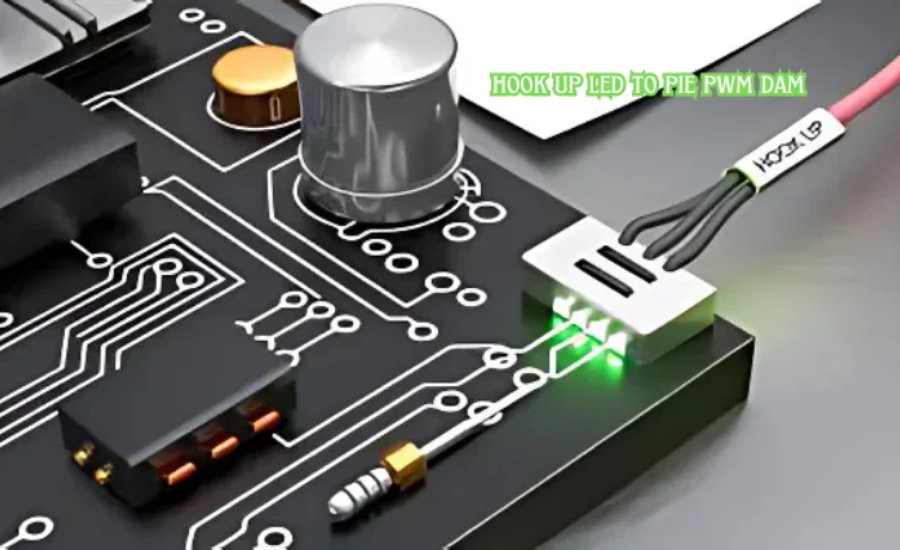

Integrating Pulse Width Modulation (PWM) technology to control LEDs and piezoelectric devices offers electronics enthusiasts a versatile and efficient way to manage power. Whether you’re a beginner or an experienced hobbyist, the ability to hook up LED to pie PWM dam enables you to control visual and auditory effects simultaneously. With PWM, you can dim LEDs, create flashing effects, and generate various tones with piezo buzzers, all while conserving energy. In this guide, we will explore the concept of PWM, how to hook up LED to pie PWM dam, and how this technology benefits your projects.

Understanding Pulse Width Modulation And Its Applications

Pulse Width Modulation (PWM) is a powerful technique used to regulate the power delivered to electrical devices. By rapidly turning the power on and off at high speeds, PWM controls the effective power supplied to connected components. The key to PWM lies in its “duty cycle” — the proportion of time the signal is active versus inactive. For instance, a 50% duty cycle means the signal is on half the time and off the other half, thus providing 50% of the full power. This on-off nature makes PWM an energy-efficient solution for a wide range of applications, especially when integrating with low-power devices like LEDs and piezoelectric buzzers.

When you hook up LED to pie PWM dam, PWM offers a creative way to control both visual and auditory outputs. LEDs can be dimmed or brightened smoothly, while piezoelectric devices can produce a range of sounds or vibrations. PWM’s efficiency stems from its on-off switching method, which significantly reduces power loss, making it an excellent choice for battery-operated systems and other low-power applications.

Key Components For Hooking Up LED To Pie PWM Dam

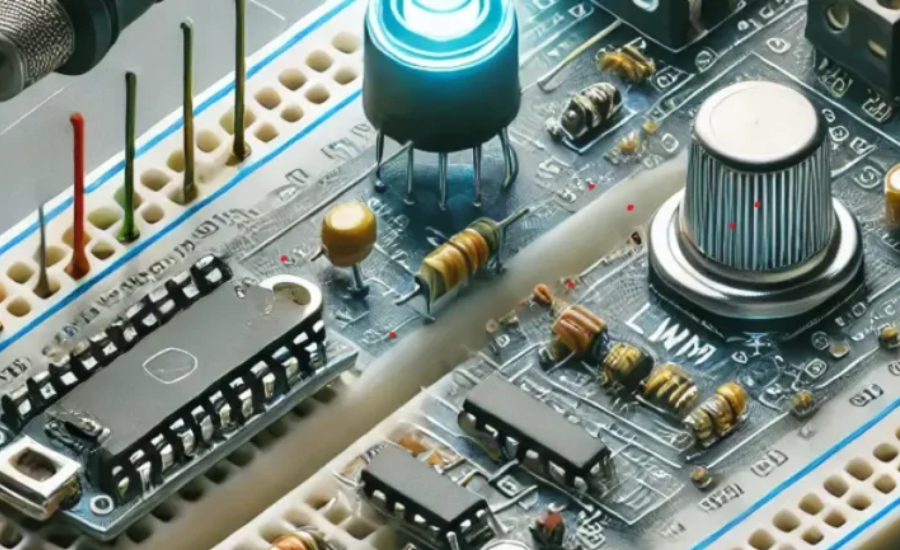

To successfully hook up LED to pie PWM dam, several fundamental components are necessary to create a functional PWM circuit. These include:

- LED (Light Emitting Diode): The LED is the primary visual output device in this setup, providing light to indicate varying PWM control levels.

- Current-Limiting Resistor: This component ensures that the LED does not draw too much current, which could cause damage. It is essential when connecting an LED to a PWM circuit to protect the component.

- Microcontroller (e.g., Arduino, Raspberry Pi): This serves as the brain of the operation, generating the PWM signal that controls the LED’s brightness and the piezoelectric device’s sound.

- Piezoelectric Device (Optional): Often used for sound or vibration, the piezoelectric device can produce various effects when paired with PWM.

- Transistor: For high-power applications, a transistor is used to amplify the signal and control larger currents than the microcontroller can handle on its own.

Together, these components work in unison to allow precise control over both the lighting and sound effects, ensuring a flexible and creative project. By using a transistor in high-power applications, you can ensure safe and effective current management when connecting LEDs or piezoelectric devices to the PWM circuit.

How PWM Controls LED Brightness In Hooking Up LED To Pie PWM Dam

PWM is a highly efficient method for controlling LED brightness. By varying the duty cycle of the PWM signal, you can adjust how much power the LED receives. A higher duty cycle, such as 80%, means the LED stays on for a larger portion of the time, making the light appear brighter. Conversely, a lower duty cycle, such as 20%, reduces the time the LED is on, resulting in a dimmer light.

Unlike traditional methods of dimming, such as using resistors, PWM allows the LED to receive full power during each “on” phase, creating a smoother dimming effect. This efficiency not only extends the life of the LED but also ensures that the device operates without excessive heat or energy waste. Thus, when you hook up LED to pie PWM dam, the PWM signal offers a more precise, controllable, and energy-efficient method for managing LED brightness.

The Role Of Duty Cycle In Hooking Up LED To Pie PWM Dam

The duty cycle of the PWM signal is the key factor in determining how the LED and piezoelectric device behave. For LEDs, the duty cycle directly impacts the brightness, while for piezoelectric devices, it controls the volume and tone. A duty cycle of 100% keeps the LED fully on, and 0% keeps it off. By adjusting the duty cycle, you can fine-tune the LED’s brightness and create a wide range of visual effects.

When you hook up LED to pie PWM dam, the duty cycle’s impact is two-fold. For the LED, a higher duty cycle results in a brighter light, while a lower duty cycle dims the LED. Similarly, in a piezoelectric device, the frequency and duty cycle of the PWM signal work together to control the pitch and volume. Higher duty cycles and frequencies generate louder and higher-pitched sounds, while lower duty cycles and frequencies produce softer and lower-pitched sounds. This versatility in controlling both light and sound is one of the primary benefits of hooking up LED to pie PWM dam.

The Function And Benefits Of Piezoelectric Devices In Hooking Up LED To Pie PWM Dam

Piezoelectric devices are commonly used for generating sounds and vibrations. These devices convert mechanical stress into electrical energy, and when connected to a PWM signal, they can create a wide range of sound effects. The frequency of the PWM signal controls the pitch of the sound, while the duty cycle adjusts its volume and tone.

When you hook up LED to pie PWM dam with a piezoelectric device, you gain the ability to control both light and sound effects with the same PWM circuit. This integration is particularly useful in projects like alarms, notification systems, or interactive displays where both visual and auditory feedback are required. By varying the PWM signal’s frequency and duty cycle, you can customize sound patterns and adjust the LED’s brightness, offering a dynamic range of effects for any project.

Step-By-Step Guide To Hooking Up LED To Pie PWM Dam

Hooking up an LED and piezoelectric device to a PWM circuit is a relatively straightforward process. Here’s a simplified guide to help you get started:

- Connect the LED: Begin by wiring the LED’s positive leg (anode) to the PWM-capable pin on your microcontroller, and the negative leg (cathode) to the ground through a current-limiting resistor.

- Set Up the PWM Signal: Program the microcontroller to generate the desired PWM signal, adjusting the frequency and duty cycle to control the LED’s brightness.

- Test the LED: Observe the LED as you adjust the duty cycle in your program, watching the brightness change as the duty cycle increases or decreases.

- Add the Piezoelectric Device (Optional): If you’re using a piezo buzzer, wire it to a separate PWM-capable pin on the microcontroller, and adjust the frequency and duty cycle to control the sound.

- Finalize Your Setup: Test the entire system to ensure that both the LED and piezo device are operating as expected, with independent control over brightness and sound.

By following these steps, you can create a fully functional PWM-controlled system where both the LED and piezoelectric device are easily manipulated.

Programming LED And Piezoelectric Control For PWM

Programming the PWM signals for both LEDs and piezoelectric devices is simple with microcontroller platforms like Arduino or Raspberry Pi. For example, in an Arduino environment, the analogWrite() function can be used to control the LED’s brightness by adjusting the PWM duty cycle. Similarly, the tone() function can generate sound on a piezoelectric device by setting the desired frequency.

By customizing the duty cycle and frequency in your code, you can experiment with different combinations to achieve various visual and auditory effects, providing an engaging experience for your projects. Whether you want to create a light show or generate custom alarm sounds, PWM gives you the flexibility to design creative, responsive systems.

Optimizing PWM Settings For LED And Piezoelectric Control

To achieve smooth, flicker-free operation, it’s crucial to select the right PWM frequency for your LED. For most applications, a frequency of at least 500 Hz is recommended, with 1 kHz or higher providing even smoother control. For piezoelectric devices, experimenting with different frequencies will help you find the perfect pitch for your desired sound, with higher frequencies producing sharper tones.

Optimizing these settings ensures that both the LED and piezoelectric devices operate at their best, delivering clear visual and auditory feedback. This level of control is what makes the integration of PWM in your projects so valuable.

Practical Applications Of Hooking Up LED To Pie PWM Dam

The ability to hook up LED to pie PWM dam opens up a world of possibilities for creative electronics projects. Some common applications include:

- Smart Lighting Systems: PWM allows you to create energy-efficient, dimmable lighting that can be controlled remotely.

- Robotics: PWM enables fine control over the brightness of LEDs for indicators and status lights, as well as sound feedback for alarms and notifications.

- Interactive Systems: Combining light and sound effects in response to user interaction creates engaging experiences in exhibits or games.

This flexibility makes PWM-controlled systems ideal for use in a wide range of fields, from home automation to entertainment.

Troubleshooting Common Issues When Hooking Up LED To Pie PWM Dam

When working with PWM-controlled circuits, you may encounter a few common issues. Flickering LEDs can often be resolved by increasing the PWM frequency, ensuring smoother transitions between on and off states. Additionally, checking the power supply and ensuring stable connections can prevent unexpected behavior. Using a proper current-limiting resistor is also crucial to protect your LED from damage.

FAQs About Hooking Up LED To Pie PWM Dam

- What is PWM?

PWM (Pulse Width Modulation) is a technique for controlling power to devices by rapidly turning the power on and off, adjusting the duration of power delivery to regulate performance, especially in devices like LEDs and buzzers.

- How does PWM affect LED brightness?

PWM controls LED brightness by adjusting the duty cycle. A higher duty cycle makes the LED brighter, while a lower duty cycle dims the light by reducing the “on” time.

- Can PWM control both LEDs and piezo devices at once?

Yes, PWM can manage both LEDs and piezo devices simultaneously, adjusting the LED’s brightness and the piezo’s tone and volume using different frequencies and duty cycles.

- Do I need a transistor for PWM?

A transistor is recommended for high-power applications to amplify the signal, but it’s not necessary for low-power setups, such as small LEDs.

- How do I program PWM for LEDs and piezo devices?

Using microcontrollers like Arduino, you can program PWM with functions like analogWrite() for LEDs and tone() for piezo buzzers to control brightness and sound.

- What are some common uses of PWM in projects?

PWM is ideal for smart lighting, robotics, and interactive systems that require both visual and sound effects, making it versatile in home automation and entertainment.

Conclusion

Incorporating PWM into your projects by connecting an LED to a piezoelectric device unlocks a wide range of creative possibilities, allowing for precise control of both light and sound effects. The efficiency of PWM ensures smooth, flicker-free dimming for LEDs, while enabling dynamic sound adjustments for piezo devices. By fine-tuning the duty cycle and frequency of the PWM signal, you can optimize performance, conserve energy, and elevate the functionality of your project. Whether you’re developing smart lighting, interactive displays, or alarm systems, PWM offers a versatile and cost-effective approach to creating more sophisticated and engaging electronic systems.

Stay tuned for the latest updates and alerts: Vents Discover!